Product Description:

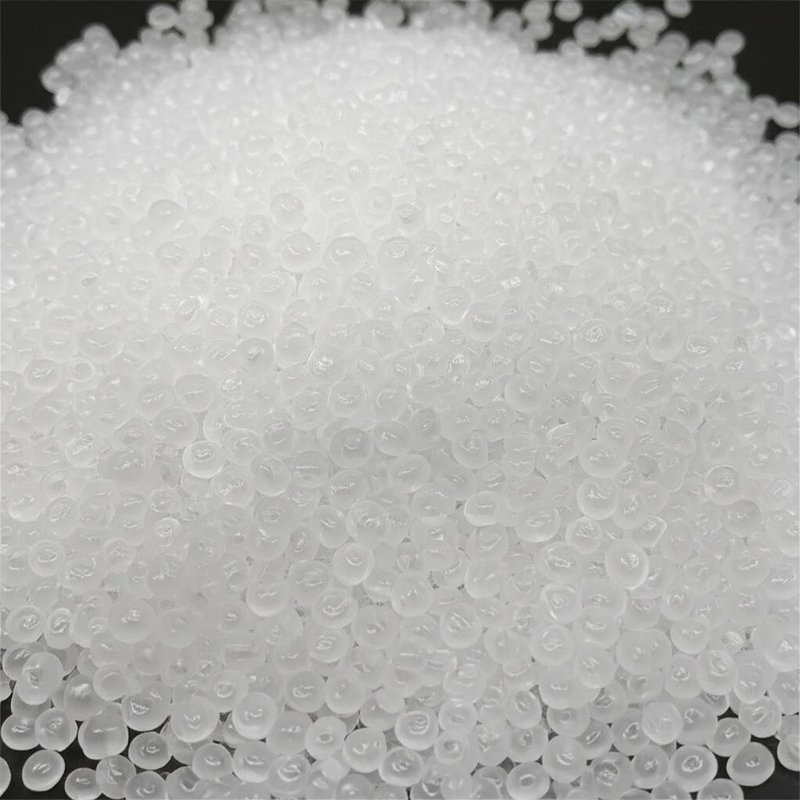

Polyvinylidene Chloride (PVDC) is a highly valued polymer known for its exceptional barrier properties and versatility in various industrial applications. This product is presented as a white powder with a volatile content of ≤ 0.10%, ensuring its purity and stability for manufacturing processes. The relative viscosity of the PVDC ranges between 1.41 and 1.46, indicating optimal molecular weight distribution that contributes to its excellent film-forming capabilities. With an apparent density of 0.80 g/ml, this PVDC powder exhibits consistent bulk characteristics ideal for processing and handling.

One of the most prominent uses of Polyvinylidene Chloride is in the production of high-performance packaging films. The PVDC Barrier Film Material is widely recognized for its outstanding barrier properties against moisture, oxygen, and other gases. This makes it an ideal choice for preserving the freshness and extending the shelf life of food products, pharmaceuticals, and other sensitive materials. The superior barrier effect of PVDC packaging films helps maintain product quality by preventing contamination and degradation caused by environmental exposure.

The white powder form of PVDC facilitates easy incorporation into various polymer blends and coating formulations. Its stable physical properties, such as the low volatile content and controlled viscosity, ensure that it can be processed efficiently into thin films without compromising mechanical strength or flexibility. This versatility allows manufacturers to produce customized PVDC barrier film materials tailored to specific packaging requirements, including cling films, shrink films, and multilayer laminates.

Packaging details for this PVDC product are standardized for convenience and safety, with each bag containing 25 kilograms of material. This packaging size is well-suited for industrial-scale production, providing sufficient quantity for continuous manufacturing runs while maintaining ease of storage and transport. The robust packaging also helps protect the PVDC powder from moisture and contamination during transit and storage, preserving its quality until it reaches the end user.

In summary, this Polyvinylidene Chloride PVDC product offers a reliable and high-quality material choice for developing advanced packaging solutions. Its excellent barrier properties, combined with a stable white powder appearance, controlled viscosity, and optimal density, make it an indispensable component in the creation of Polyvinylidene Chloride Packaging Film. Whether used as a standalone barrier or as part of a multilayer film system, PVDC Barrier Film Material enhances the protective performance and longevity of packaged goods.

Manufacturers seeking to improve the functional attributes of their packaging films will find this PVDC product an excellent candidate for their formulations. Its consistent quality and carefully controlled specifications ensure reproducible results and superior end-product performance. By incorporating this PVDC Barrier Film Material, producers can achieve packaging solutions that not only meet but exceed industry standards for barrier effectiveness and durability.

Features:

-

Product Name: Polyvinylidene Chloride (PVDC)

-

Apparent Density: 0.80 g/ml

-

Relative Viscosity: 1.41–1.46

-

Volatile Content: ≤ 0.10 ω/%

-

Appearance: White Powder

-

Packaging Details: 25Kg/Bag

-

Ideal for producing Polyvinylidene Chloride Film

-

Excellent PVDC Barrier Film Material properties

-

High-quality Polyvinylidene Chloride Plastic for various applications

Technical Parameters:

|

Apparent Density (g/ml)

|

0.80

|

|

Packaging Details

|

25Kg/Bag

|

|

Residual Vinylidene Chloride (ppm)

|

≤ 3

|

|

Volatile Content (ω/%)

|

≤ 0.10

|

|

Relative Viscosity

|

1.41–1.46

|

|

Appearance

|

White Powder

|

Applications:

RUNYE Polyvinylidene Chloride (PVDC) Resin, originating from China, is a high-quality white powder product designed to meet the demanding needs of various industrial applications. With a minimum order quantity of 1 ton and a supply ability of 1000 tons per month, RUNYE ensures consistent availability and reliable delivery for manufacturers worldwide. The product is carefully packaged in 25Kg bags to maintain its integrity and facilitate easy handling during transportation and storage.

Thanks to its unique chemical structure and superior properties, RUNYE PVDC Barrier Film Material is widely used in the production of high-performance barrier films. These films exhibit exceptional resistance to gases, moisture, and odors, making them ideal for food packaging applications where product freshness and shelf life extension are critical. The low volatile content (ω/%) of ≤ 0.10 and a residual vinylidene chloride level of ≤ 3 ppm ensure that the polymer meets stringent safety and environmental standards, further enhancing its suitability for sensitive packaging scenarios.

In addition to food packaging, RUNYE Polyvinylidene Chloride Barrier Polymer is extensively utilized in pharmaceutical packaging, where maintaining the integrity and protection of medicinal products is paramount. Its excellent barrier properties help prevent contamination and degradation caused by external factors such as oxygen and moisture. Moreover, the relative viscosity range of 1.41–1.46 provides optimal processing characteristics, allowing manufacturers to produce films with consistent thickness and mechanical strength.

Beyond packaging, RUNYE Polyvinylidene Chloride Resin finds applications in specialty coatings and laminates, contributing to enhanced durability and chemical resistance of various materials. Its white powder appearance facilitates easy blending with other polymers and additives, enabling customization for specific end-use requirements. Industries such as electronics, cosmetics, and industrial goods also benefit from the versatile performance of this PVDC Barrier Film Material, leveraging its protective qualities to improve product longevity and quality.

Overall, RUNYE PVDC Barrier Film Material is an indispensable component in modern manufacturing, offering reliable barrier performance, safety compliance, and processing efficiency. Whether used in food packaging, pharmaceutical wraps, or specialty coatings, this Polyvinylidene Chloride Barrier Polymer stands out as a premium choice for businesses seeking high-quality, consistent, and effective barrier solutions.

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!  Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten!

Ihre Nachricht muss zwischen 20 und 3.000 Zeichen enthalten! Bitte überprüfen Sie Ihre E-Mail!

Bitte überprüfen Sie Ihre E-Mail!